May 06, 2023

5085

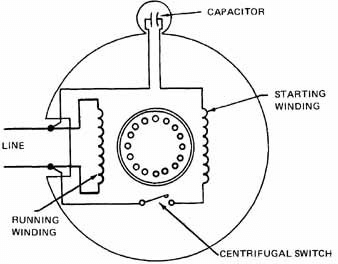

The motor centrifugal switch is a common electrical component that monitors the speed of the motor when it is running and automatically cuts off power when the speed reaches a certain value to protect the motor from damage. The centrifugal switch is used as long as it is used to control the starting coil of a single-phase motor.

Electronic Centrifugal Switches ( SAMUSCO )

The centrifugal switch consists of two parts:

(1) A centrifugal mechanism that rotates around the motor shaft

(2) A fixed switch with an electrical contact device to control the starting coil.

Centrifugal Switch

(1) the one without centrifugal switch, single capacitor phase shift type, such as those for electric fans, which are usually used for small motors

(2) the one with centrifugal switch, single capacitor phase shifting start type, such as some fans and other equipment, but for various reasons, this kind of motor seems to be less and less. But in some special places, indeed it still exists.

(3) the one with centrifugal switch, double capacitance double value phase shift type, is most common in many places, such as air compressors, cutting machines, bench top electric drills and other places.

It is used in single-phase motors, mounted on the motor rotor, and the circuit is connected in series in the starting circuit.

The switch is turned on when the rotor is at rest and turned off when a certain speed is reached.

When starting, the starting circuit is started through the centrifugal switch, and when a certain speed is reached, the centrifugal switch is disconnected and the starting circuit is automatically cut off.

The centrifugal block has a complicated structure and is prone to failure and even burned auxiliary windings. And the switch is installed inside the motor, so it is not convenient to repair the problem. Therefore, single-phase asynchronous motors nowadays are less likely to use centrifugal switches as starting devices and instead use various types of starting relays. The starting relay is usually installed on the top of the motor case, which is convenient for maintenance and inspection. Commonly used relays are voltage, current, and differential type.

Centrifugal switch in single phase motor is a kind of protection device commonly used for single phase motor. It protects the motor from overload and overheating by closing the switch by centrifugal force when the motor starts.

The single-phase motor centrifugal switch consists of a centrifugal mechanism, terminals and contacts. When the motor starts, the centrifugal mechanism is subjected to centrifugal force, which causes the contacts to close and the motor to operate normally. When the motor malfunctions, such as overload and overheating, the centrifugal mechanism is affected and the contacts are broken, thus protecting the motor.

Centrifugal switch is not configured for all single-phase motors, and the device centrifugal switch should be special motor.

Double duty capacitor single-phase motors may have centrifugal switches

Capacitor-started single-phase motors without capacitor operation may have centrifugal switches

Resistance-started single-phase motor has centrifugal switch.

Single-phase deep well pump does not have centrifugal switch

To know whether a single-phase motor has a centrifugal switch or not, just look at whether it is the above starting method.

Single-value capacitor single-phase motor can't remove the capacitor after starting. If you remove the capacitor, the power will drop and the motor will overheat.

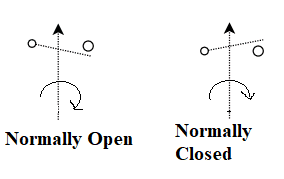

The symbol of the centrifugal switch is a circle with a plus sign in the middle, indicating the closed state of the switch.

The symbol for the centrifugal mechanism is a triangle, indicating the role of the centrifugal mechanism.

Symbol of the Centrifugal Switch

1. Protect the motor When the motor is overloaded or overheated.

2. Extend the life of the motor Through the protective effect of the centrifugal switch.

3. Improve the efficiency of the motor.

Motor centrifugal switches are widely used in various motors, such as fans, pumps, compressors, etc. In these devices, motor centrifugal switches play an important role in protecting the motor from damage due to overload or overspeed. In addition, motor centrifugal switches can be used to control the starting and stopping of motors to improve the safety and reliability of the equipment.

Single-phase induction motors

Compressors

Pumps

Fans

Blowers

Power tools

Industrial machinery