At Censtry, we aspire to be the go-to source for engineers and buyers, offering services for electronics design, prototyping, testing, and manufacturing. See our Quality Policy, Quality Manual, and Certificate. Our commitment to customer satisfaction, order precision, and on-time delivery defines our customer service excellence

84% of our suppliers originate directly from the original manufacturers or reputable global distributors, while 16% are meticulously chosen from verified authentic OEMs or stockists

All our shipments are entirely traceable back to their origins and respective Manufacturers, ensuring transparency and authenticity.

Equipped with a comprehensive range of testing apparatus, our in-house lab ensures stringent quality control measures.

We continuously refine our procedures to exceed customer requirements, delivering products that meet all specifications and demonstrate reliability throughout their lifecycle

Censtry collaborates with White Horse Laboratories and CECC Laboratories to uphold global procurement and Supply Chain Management commitments. Our testing, inspection, and packaging units were established in response to the proliferation of substandard and counterfeit electronics

We offer test reports and product quality verification for nearly all components before shipment. Our extensive network of in-house labs, certified through third-party accreditation, ensures thorough and reliable testing, minimizing risks for our customers

We offer comprehensive electronic component testing services, crucial in detecting fake components. Most parts undergo functional testing to prevent any faulty or counterfeit products from reaching the market

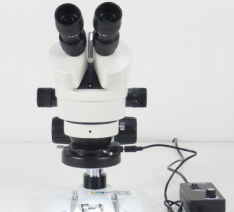

High-Resolution Microscope: Offers high magnification, clarity, and inspects microstructures, markings, and surface details of components. Enables observation of surface conditions and microstructural features.

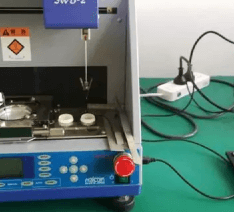

Solderability Tester: Evaluates components' soldering capabilities by examining their reliability in creating solder joints. Ensures adherence and reliability, optimizing soldering performance and durability

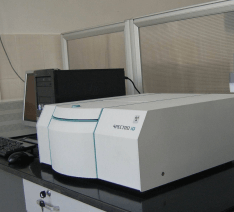

XRF Spectrometer: This equipment detects elemental compositions within materials, analyzing the chemical makeup of components to confirm material authenticity and compliance.

X-Ray Transmission Equipment: This apparatus examines the internal structure of components using X-rays to identify concealed irregularities or alterations within the components' internal structure.

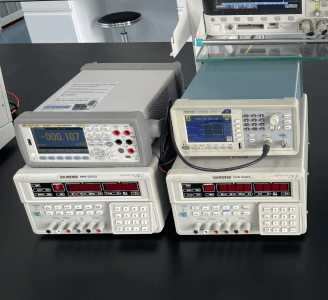

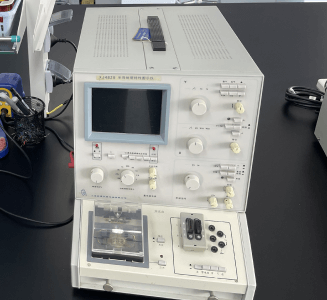

Key Functional Teste:Tests vital electronic component parameters like voltage, current, power, timing, frequency, phase, noise, and distortion. Provides engineers with accurate data to assess compliance with design specifications.

Electrical Performance Tester:Tests electrical performance parameters such as resistance, capacitance, inductance, conductivity, breakdown voltage, noise, and distortion. Provides precise data for engineers to evaluate compliance with design requirements.

Laser Decapsulator:Non-destructively opens electronic component packaging using a laser beam. Facilitates internal inspection, maintenance, and rework without causing damage.

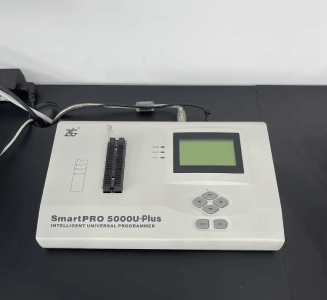

Programmer and Burn-in Instrument:Writes programs or data into electronic component memory using programming circuits. Assists in programming, burning, and testing components

Ensuring the component's appearance is flawless, without damage or anomalies.

Confirming the compliance and validity of certification documents

Verifying the component's traceability back to the original manufacturer.

Utilizing non-destructive testing methods such as X-rays to inspect internal structures

Analyzing the materials within the component to ensure they meet specifications

Assessing the component's functional performance to meet standards.

Evaluating performance and corrosion resistance under varying temperature and humidity

Verifying the accuracy and compliance of labels on the components

Ensuring completeness of certification documents and assessing packaging conditions

An in-depth examination of the component's appearance, focusing on minor imperfections.

Evaluating chip integrity through decapsulation and die assessment

Providing detailed reports summarizing all testing outcomes and findings.

01

01

02

02

03

03