July 29, 2021

2500

Wearable health sensors have long been on the market, and an absorbable Proteus-type sensor has also been born (has passed the FDA (Food and Drug Administration) review), and the application of sensors in the field of medical electronics is not uncommon.

The Proteus-type sensor can completely contact the gastric juice when it is in the stomach, and then will transmit a unique signal according to the timing of ingestion. These signals are transmitted through body tissues to a battery-powered patch on the skin, so that various signals and physiological and behavioral indicators such as heart rate, body position and activity can be detected. Of course, the last type of Proteobacteria sensor will flow out of the body like high-fiber food, and will generally maintain a lifespan of 7 days.

Pressure sensor

A pressure sensor is a transducer that converts force or gravity into electrical signals. Pressure sensor applications are called medical pressure sensors in medicine, and they must be highly accurate and compactly packaged to facilitate carrying, especially when the device is to be directly connected to the patient. If the sensor is used in a monitoring instrument integrated with a medical device, standard packaging materials such as stainless steel and anodized aluminum should be used. If the equipment is in direct contact with the human body or liquid, special stainless steel or disposable sensors that can be autoclaved can be used. The following figure shows the application of pressure sensors in medical treatment.

Medical pressure sensors were used for bed load monitoring in the early days, and now small pressure sensors are applied to areas that are prone to human error, such as infusion pumps used for drug delivery. In order to adjust the flow rate as accurately as possible and to facilitate monitoring by nurses at any time, people apply pressure sensors to infusion pumps. This sensor can accurately measure the weight of the infusion bag. When the weight of the liquid is different from the preset value, the sensor will immediately send a warning message to the connected device and communicate with the controller in time.

Non-contact temperature sensor

Generally speaking, non-contact thermometers can measure the heat emitted from a remote infrared radiant heat source. In the absence of a clear fiber optic temperature sensor or an infrared fiber and infrared sensor combination license, the non-contact surface has a clear line of sight. This may help determine the surface temperature of fast-moving objects, even measuring temperature in narrow places and electromagnetic fields. AgClxBr1-X is considered to be the best choice for low temperature measurement. These fibers are characterized by being flexible, insoluble in water, and non-toxic. For this reason, silver halide infrared optical fibers are used in infrared spectroscopy, as well as radiation measurement and thermal imaging in industrial and medical applications.

biological sensor

The biosensor is sensitive to biological substances and converts its concentration into electrical signals for detection. It uses immobilized biologically sensitive materials as identification elements (including enzymes, antibodies, antigens, microorganisms, cells, tissues, nucleic acids and other biologically active substances). Appropriate physical and chemical transducers (such as oxygen electrodes, photosensitive tubes, field effect tubes, piezoelectric crystals, etc.) and analysis tools composed of signal amplification devices.

In clinical medicine, the enzyme electrode is the earliest developed and most used sensor. Using microorganisms with different biological characteristics instead of enzymes can be made into microbial sensors. Biosensors have been used to monitor a variety of bacteria, viruses and their toxins. The typical representative product of the biosensor for drug analysis is the SPR biosensor, which is a surface membrane resonance analysis that is a technology for real-time determination of the binding of biomolecules.

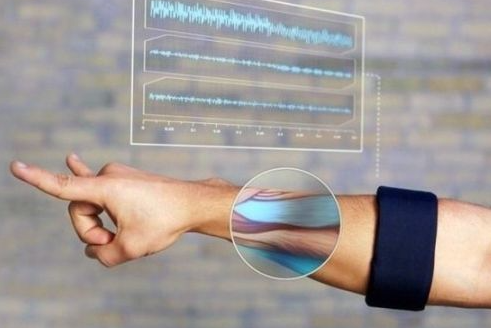

Implantable sensor

Implantable sensors are small, light, and compatible with the body, and require very low power. More importantly, they cannot decay over time.

The power requirement is one of the main challenges facing the normal operation of implanted sensors. The sensor that does not need power to function is the most perfect, but there is no such sensor on the market. The piezoelectric polymer sensor is small in size, high in reliability, does not require external power, and can work continuously for a long time. This type of sensor can be applied to a pacemaker that monitors patient activity. As shown in the figure below, the implanted sensor can monitor heart rate changes in real time. For example, because a large aneurysm grows in the abdomen, it is necessary to remove a part of the fragile artery and replace it with a synthetic tubular organ. At this time, a sensor can be implanted during the operation to monitor pressure leakage at the surgical site.

Other uses of sensors in medical treatment

Nowadays, sensors have been widely used in various monitoring instruments. Monitors are used in diagnosis and treatment environments (such as operating rooms, emergency rooms, intensive care units, intensive care units, and increasingly common patient families) to monitor and display various main conditions of the patient’s body, including electrocardiogram, pulse oximetry, and blood pressure , Respiration, temperature, etc. The monitor can be an independent instrument or a multi-parameter instrument.

The role of the oxygen generator is to reduce the nitrogen in the air delivered to the patient while increasing the proportion of oxygen. The oxygen concentrator is used for patients who cannot smoothly absorb oxygen into the blood, such as some patients with lung diseases. Since the airflow sensor used in the oxygen generator must be able to measure ultra-low flow, such as 0.1 cubic centimeters of flow, the airflow sensor can be used to detect when the patient begins to exhale (that is, when the air flow should be reduced), so that the patient Exhale easily and feel comfortable.

The low and ultra-low pressure plastic-encapsulated silicon pressure sensor can detect the moment when the patient starts to inhale, so as to effectively and efficiently deliver oxygen. This not only shortens the reaction time of the system, but also avoids the supply of oxygen when the patient is not inhaling. Waste. Therefore, the operating efficiency of the oxygen generator can be improved without the need for a bulky oxygen generator. The oxygen generator is small in size, consumes less power, and is easy to carry. This stainless steel media-isolated pressure sensor can also detect the pressure of the buffer tank, and at the same time can feed back a signal to the compressor to keep the compressor at a proper pressure.