May 29, 2021

2307

The global industrial intelligence process continues to advance, and the industrial automation industry market has also been attracting attention. This time, we invited their customers through the technology-based distributor Shijian, a hardware engineer currently working for a domestic first-line industrial automation manufacturer, to discuss high-performance AO technology with us.

Li Gong's first-line industrial automation manufacturer is oriented to autonomous control, smart management, safe and reliable, and provides intelligent manufacturing products and solutions with automation control system as the core, covering industrial software, automation instrumentation, and operation and maintenance services. And Li Tool has 7 years of experience in electronic system design and serves as the IO technical architect of the control system. Possess rich design experience in analog-to-digital mixed circuits and signal chain circuits.

1. Why do we need high-performance AO technology?

With the development of the automation industry, industrial control systems are constantly being upgraded in the direction of stronger performance, higher reliability, and smarter applicability. As the interface between the control system and industrial equipment, the IO system also needs to continuously upgrade its performance to meet the higher operating requirements of the control system and industrial equipment.

The AO (Analog Output) equipment in the industrial control system is an important component of the IO system. As the "hand" for the control system to operate industrial equipment, AO equipment determines the operating status of field equipment by outputting voltage and current signals. Therefore, the performance of the AO equipment determines the execution level of the control results of the control system on the industrial equipment. At present, the mainstream AO devices on the market support current and voltage signals, the signal accuracy is roughly between 0.2% and 0.5%, and the signal refresh speed is between ten milliseconds to tens of milliseconds.

The driving objects of AO equipment not only include various valve actuators, but also motor equipment, electromagnetic equipment, lighting equipment and so on. In some high-end applications, the requirements for control accuracy and speed have exceeded the mainstream AO performance on the market. In some applications, additional signal isolation or conversion equipment is required between the AO equipment and the actuator, which leads to a decrease in AO output performance. In order to adapt to high-precision and high-speed actuators, or to reduce the impact of signal isolation or conversion equipment on system performance, the output performance of AO equipment needs to be further improved.

2. What AO technology do we need?

On the surface, we need to improve the signal accuracy and refresh speed of AO equipment, but after in-depth analysis, this is an extremely complicated problem.

The signal types of AO equipment are common voltage signals and current signals. The standard industrial voltage signal is 0V~5V, 1V~5V, and the standard industrial current signal is 0mA~10mA, 4mA~20mA. In addition, there are some non-standard signal ranges. In terms of port characteristics, the voltage signal output requires the port output low impedance, and the current signal output requires the port output high impedance. In practical applications, due to the requirement of driving capability and the limitation of the feedback structure, the design of the port output impedance must take into account both voltage and current, which brings a certain degree of design complexity.

Control systems used in industrial sites often need to face complex environmental conditions, especially installation space, ventilation conditions, and ambient temperature. The appearance design of the AO equipment needs to be as compact as possible, and the volume of the AO circuit is required to be as small as possible. To maintain high accuracy even under the conditions of small size and wide temperature, it is necessary for the circuit components to have lower temperature drift, or to reduce the temperature rise of the AO circuit as much as possible.

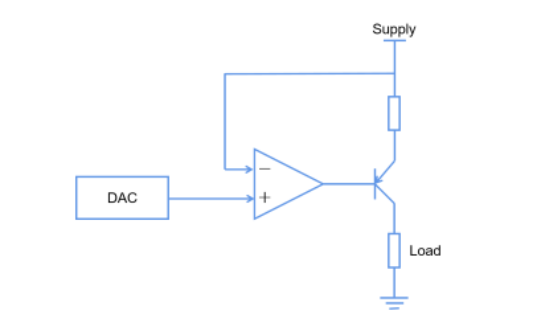

Figure 1 is a common voltage-to-current AO output scheme. In order to make the load current adjustable, the tube voltage drop of the output stage triode needs to be changed in a wide range. Under certain load conditions, the heat generation of the transistor will be very high. If the heat dissipation capacity of the AO device is not enough to offset the heat, components such as DAC and op amp will have a large accuracy error due to large temperature drift.

AO components in PLC and DCS equipment often have more than one AO output. When a single AO component accommodates multiple AO outputs, problems such as circuit design complexity, circuit scale and space conflict, and heat generation will be more serious. This has led to the improvement of the performance of AO equipment, which is difficult to achieve with the reliability and ease of use of AO equipment.

In short, high-performance AO technology needs to further optimize port compatibility, improve circuit integration, and reduce heat generation and the impact of heat generation on the basis of improving signal accuracy and refresh speed. Traditionally, signal chain circuit solutions based on discrete device designs are difficult to meet various requirements.

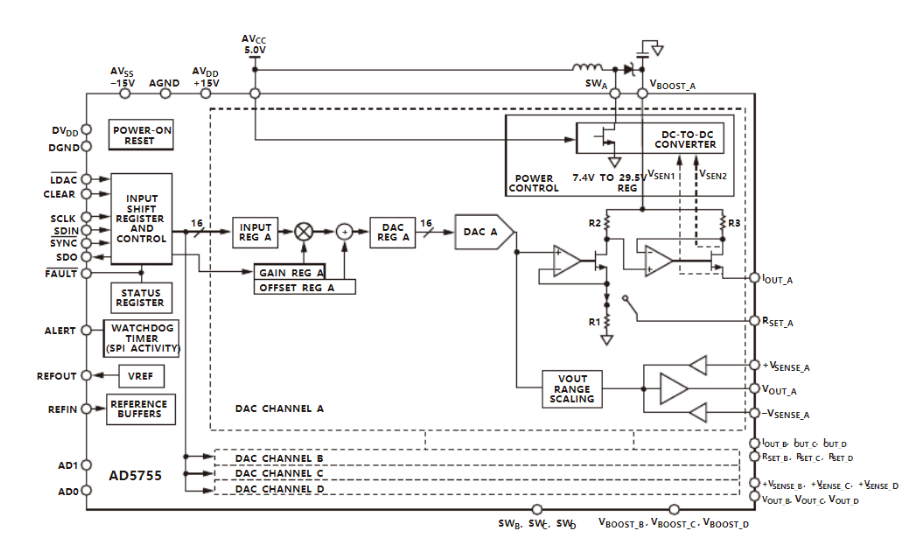

Three, AD5755 program

The AD5755 introduced by ADI solves the above problems perfectly. This DAC is packaged with 4 independent voltage and current output circuits, each of which can independently output voltage-type signals or current-type signals. AD5755 supports a maximum signal range of ±10V and 0mA~24mA, which basically covers all signal types in industrial equipment applications.

AD5755 has designed a BOOST controller for each AO unit. Its function is to automatically adjust the output voltage of the AO signal power supply according to the signal output and load conditions of the current channel. As can be seen from the example in Figure 1 above, when the voltage value of the AO output power supply can be adjusted according to the output feedback, the tube voltage drop of the drive tube of the output stage can be limited to a preset value, such as 2.4V At this time, the heating power of the driving tube becomes very low, and the largest heat source in the entire AO circuit is greatly restricted. Solve the problem from the heat source, and the heat and heat dissipation of the entire AO component will be greatly improved.

The AD5755 solution integrates 4 sets of DACs, operational amplifier stages, power amplifier stages and other traditional signal chain structures, as well as a self-adjusting power supply controller, into one chip, replacing the huge circuit scale and design workload when discrete component designs were used in the past. The chip area is only 9mm*9mm, which greatly reduces the circuit area and the volume of AO equipment. At the same time, the self-regulating power controller is used in conjunction with the AO unit, which effectively solves the temperature drift and aging problems caused by circuit heating. It further improves the environmental adaptability of the signal accuracy and the reliability of the circuit.

According to ADI's official manual, AD5755 can achieve a basic accuracy of 0.05%, and its dynamic response time is as low as ten to several tens of microseconds, which is far higher than mainstream products in the existing market in terms of accuracy and speed. It is an ideal solution for the next generation of high-performance AO system.

In addition to important indicators such as accuracy and speed, AD5755 also has a HART signal modulation input function for the needs of intelligent instruments. We only need to add an independent HART Modem, input the HART signal into the CHART pin of AD5755, and then directly output the current signal with HART communication at the Iout end.

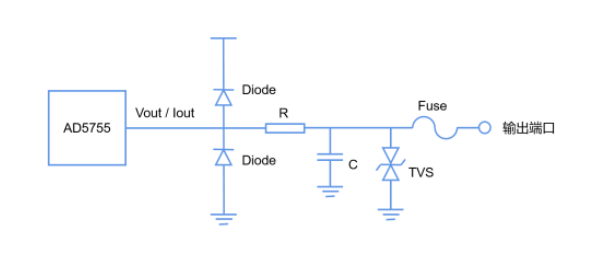

When using AD5755 to design AO equipment, it is only necessary to focus on the protection of the chip. We can add necessary protection circuits such as RC, LC, magnetic beads, TVS, self-resetting fuses, etc. to the ports, which can greatly improve the withstand capability of the system. The figure below shows a more general protection scheme for readers' reference only.

Through the comparison between the traditional solution and the AD5755 solution, it is not difficult to find that the traditional process method based on electronic components + PCB has its own bottleneck. The bottleneck that is difficult to break under the framework of traditional craftsmanship can be easily solved in the face of advanced craftsmanship (such as MEMS or Chip, etc.). We look forward to the emergence of more highly integrated chip solutions or module solutions in the market in the future to provide us with product design resources with stronger performance, higher reliability, and smarter applicability.