June 16, 2021

2238

The concept of new energy vehicles has repeatedly swept the capital market, attracted wide attention from consumers, and kept attracting the attention of industry giants. It is estimated that by 2025, the sales volume of new energy vehicles in China will reach about 20% of the total sales of new vehicles, while the current figure is between 4% and 5%, reflecting the future market growth of at least three times.

New energy vehicles include hybrid electric vehicles (HEV) and fuel cell electric vehicles (FCEV) and other technical routes. However, at present, new energy vehicles generally only refer to the pure electric vehicle route, that is, the familiar Tesla and a group of new car-making forces. The core component of pure electric vehicles is: lithium batteries.

As a new type of clean energy, lithium batteries can not only power new energy vehicles, but also power various products such as electric trains, electric bicycles, and golf carts. The production of lithium batteries is closely linked by one process step. The production process roughly includes pole piece manufacturing, battery cell manufacturing, and battery assembly. Therefore, the quality of lithium batteries directly determines the performance of new energy vehicles, which puts strict requirements on their manufacturing technology and equipment. Laser technology represented by laser welding and cutting, as an advanced "light" manufacturing tool, exhibits the characteristics of high efficiency, precision, flexibility, reliability and stability, low welding material loss, automation and high degree of safety, and is widely used in the manufacturing process of power lithium batteries. in.

Application of laser processing technology in the field of new energy lithium battery

01, laser cutting

Lithium battery processing requires high accuracy, controllability, and the quality of processing machines. Before the advent of laser technology, the lithium battery industry usually used traditional machinery for processing and cutting, but traditional die-cutting equipment would be difficult to use during use. Avoid wear and tear, dust falling and burrs, which may cause various dangerous problems such as battery overheating, short circuit, and even explosion.

In order to avoid danger, it is more suitable to use laser for cutting. Compared with traditional mechanical cutting, laser cutting has the advantages of no tool wear, flexible cutting shape, edge quality control, higher accuracy and lower operating costs. It is conducive to reducing manufacturing costs, improving production efficiency, and greatly shortening new product molds. Cut cycle. Lithium batteries, as the core components of new energy vehicles, directly determine the performance of the entire vehicle. With the gradual explosion of the new energy vehicle market, laser cutting will have great market potential in the future.

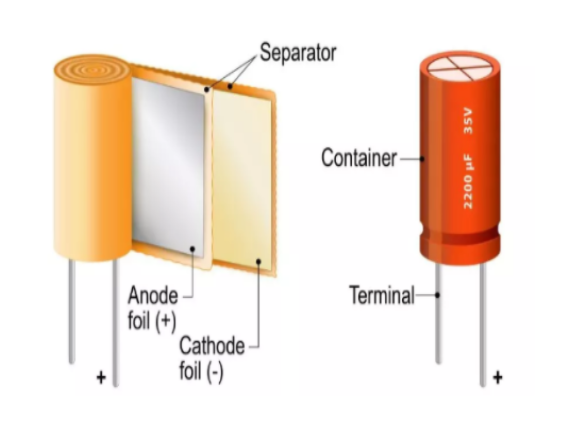

The production steps of lithium batteries are a typical "roll-to-roll" process, which involves processing from thin films to individual batteries and the assembly of individual batteries into a battery system. A typical lithium battery has three films-anode film, separator film and cathode film, as shown in the figure below.

The electrode coating thickness is usually 100 μm, while the separator is 50 μm. The anode film is a copper film coated with graphite, the cathode film is an aluminum film coated with lithium metal oxide, and the isolation film is composed of polypropylene and polyethylene.

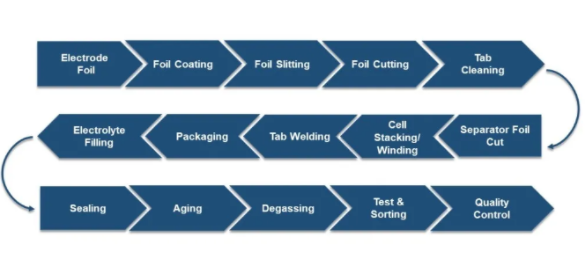

Lithium battery production process

Due to the high requirements for accuracy, controllability and quality of processing machines, metal foil slitting (foil slitTIng), metal foil cutting (foil cutTIng) and separator foil cutting (separator foil cutTIng) need to be applied to the cutting process. It is more suitable for laser processing.

Foil slitTIng

The metal foil slitting process refers to cutting a roll of metal foil into thin strips along the long side according to the design of the battery. The infrared pulse laser is suitable for this link, which can slit the electrode coating with high speed and high quality. If there are more precise requirements for slitting width and quality, pulsed green light and ultraviolet light can also be considered.

Foil cutting

The metal foil cutting process refers to cutting the elongated anode film and cathode film into the required shape with reference to the design of the battery. Depending on the battery design and whether the metal foil roll is completely coated, you can choose or adjust the beam to cut the coating or only cut the metal foil. The applicable laser in this link is the same as the aluminum foil slitting link.

Separator foil cutting

Similar to aluminum foil cutting, the cover film should also be cut into the required shape with reference to the battery design. Because the isolation film is composed of organic compounds, pulsed ultraviolet lasers are the most suitable choice.

02, laser welding

There are more than ten steps in the production of a lithium battery, and the role of the laser welding machine is to provide customers with a complete set of lithium battery production equipment to ensure the battery's range and safety during operation. Compared with traditional argon arc welding, resistance welding and other methods, laser welding has significant advantages: first, the heat-affected zone is small, second is non-contact processing, and third is high processing efficiency. From the perspective of laser welding, the main welding materials for lithium batteries include aluminum alloys and copper alloys. The shape of the battery casing is mainly divided into square and cylindrical. At present, the popularity of prismatic batteries in China is relatively high. The welding methods mainly include splicing welding and stack welding. In the field of new energy lithium batteries, laser welding technology has been used on a large scale for welding tabs, battery cell shells, sealing nails, flexible connections, explosion-proof valves, battery modules, etc.

The laser welding energy is concentrated, the welding efficiency is high, the processing accuracy is high, and the welding seam aspect ratio is large. The laser beam is easy to focus, align, and be guided by optical instruments. It can be placed at an appropriate distance from the workpiece, and then guided between fixtures or obstacles around the workpiece. During the working process, the heat input of the laser beam is small, the heat-affected zone is small, the residual stress and deformation of the workpiece are small, and precise welding can be achieved. Since the cell of the power battery follows the principle of "portability", the material is generally aluminum alloy and thin, so the shell, cover, and bottom are generally required to be below 1.0 mm. The current basic material thickness of mainstream manufacturers is about 0.8 mm. In order to weld these sheets together, it is necessary to use laser welding.

03, laser cleaning

The production of lithium batteries includes three parts: pole piece manufacturing, battery cell manufacturing and battery assembly. Adding laser cleaning to the three manufacturing processes can greatly improve the battery manufacturing process level.

Laser cleaning before pole piece coating

The positive and negative plates of lithium batteries are made by coating lithium battery positive and negative materials on thin metal strips. When the electrode materials are coated on the thin metal strips, the thin metal strips need to be cleaned. The thin metal strips are generally aluminum thin or thin metal strips. The copper is thin, and the original wet ethanol cleaning is easy to cause damage to other parts of the lithium battery. The laser dry cleaning machine can effectively solve the above problems.

Laser cleaning before battery welding

Using pulsed laser direct radiation decontamination, the surface temperature rises and thermal expansion occurs. The thermal expansion causes the contaminants or the substrate to vibrate, so that the contaminants overcome the surface adsorption force and detach from the substrate surface to achieve the purpose of removing the surface stains of the object. This method can effectively remove dirt, dust, etc. on the end face of the battery pole to prepare for battery welding in advance to reduce defective welding products.

Laser cleaning during battery assembly

In order to prevent safety accidents of lithium batteries, it is generally necessary to apply external glue treatment to the lithium battery cells to play the role of insulation, prevent the occurrence of short circuits, protect the circuit, and prevent scratches. Laser cleaning the insulating plates and end plates, cleans the dirty surface of the cell, roughens the cell surface, improves the adhesion of glue or glue, and does not produce harmful pollutants after cleaning. It is an environmentally friendly green cleaning method. This is becoming more and more important in the context of the global attention to environmental protection.

Tab cleaning

Under certain circumstances, graphite and lithium metal oxide need to be removed to reveal bare copper or aluminum foil labels. The key to this step is to remove the coating material without damaging the metal foil below it. The technology suitable for this link is pulsed infrared laser.

04, laser marking

Laser marking has fast speed, high production efficiency, and good rendering effect. Therefore, it has been gradually used in the production and processing of lithium batteries, and the equipment has long service life, simple operation and no consumables, which can effectively save costs and labor. During the processing of lithium batteries, lasers can be used to mark the surface with codes, characters, production date, anti-counterfeiting codes and other information, which will not only not damage the lithium battery, but also improve the overall aesthetics of the battery. The characteristic of laser marking is non-contact. It can be printed and marked on the surface of any regular or irregular object. After the workpiece is marked, there will be no internal stress and deformation, which not only guarantees the original accuracy of the workpiece, but also does not It causes corrosion, abrasion, poisoning and pollution to its surface, which greatly improves the processing efficiency.