May 18, 2021

2422

MEMS (Micro-Electro-Mechanical System) microphones are tiny devices that provide high-fidelity sound perception. They are small in size and can be tightly integrated into electronic products such as smart phones, smart speakers, and headsets. Now, MEMS microphones can not only record ordinary environmental sounds, but also have functions such as stereo sound, active noise reduction, directivity (bunching), and voice recognition. These audio functions can be achieved by increasing the number of microphones in the device. For example, the number of MEMS microphones in the latest smart phones can be as many as 6. The outstanding performance makes MEMS microphones have a wide range of applications, which has created a large amount of market demand.

What is a capacitive MEMS microphone? How does it work?

All microphones (traditional microphones and MEMS microphones) sense sound waves through a flexible diaphragm. Under sound wave pressure, the diaphragm will be displaced. Most MEMS microphones on the market now use capacitive technology to detect sound. The working principle of a capacitive MEMS microphone is to measure the capacitance between a flexible diaphragm and a fixed backplane. The change in air pressure caused by sound waves will cause the diaphragm to shift. Air can pass through the small holes on the back plate, so the position of the back plate will not change. During the movement of the diaphragm, the distance between the diaphragm and the fixed backplane will change, which will eventually lead to a change in the capacitance value between the two. This electrical signal change can be recorded and analyzed.

There are different types of capacitive MEMS microphones, such as:

Single back panel microphone

Double-layer backplane microphone, with separate diaphragms on both sides of the backplane

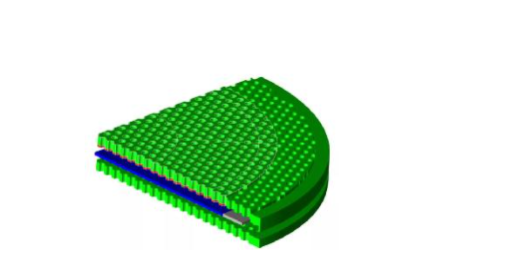

The backplane of a double-layer diaphragm microphone is encapsulated between two layers of diaphragms, and the space between the diaphragms can be vacuum.

Example of a MEMS+ model of a double-layer backplane MEMS microphone

MEMS microphone design

MEMS microphone designers need to study and optimize key performance indicators such as frequency response, sensitivity, signal-to-noise ratio (SNR), total harmonic distortion, and equivalent input noise. The signal-to-noise ratio is a key performance indicator. Different capacitive MEMS microphones improve the signal-to-noise ratio by increasing the signal (double-layer backplane and double-layer diaphragm) or reducing noise (vacuum sealing between the two diaphragms) SNR.

The design, modeling and research of capacitive MEMS microphones and their performance characteristics can be carried out in MEMS+® (part of the CoventorMP® MEMS design platform). MEMS+ provides nonlinear and multi-physical parameter models of different MEMS structures. These models can form a complete MEMS microphone design. In addition, MEMS+ microphones can be integrated into Cadence Virtuoso® circuit simulation software, which will allow us to simulate MEMS microphones and their ASICs through specific IC bias conditions.

Future MEMS microphone design

In the era of artificial intelligence, MEMS design schemes based on innovative automatic optimization technology have appeared on the market. For example, a group from the School of Electronic Design Automation of the Technical University of Munich has studied and demonstrated MEMS+-based MEMS microphones including its readout circuit automation optimization design.