November 01, 2023

829

From assisting in surgical procedures to lifting heavy loads in manufacturing plants, robots have provided convenience in many aspects of our lives. The impact of robots on the modern world is evident, but have you ever wondered how robot systems achieve such precise, fast, and powerful movements? If the answer is through motors, then congratulations, you're correct!

Robots often mimic tasks that would typically be performed by humans; thus, their functions mainly involve adjusting position and direction through some form of displacement or rotation, which is typically achieved through motors.

Traditional robot applications have primarily focused on mechanical movements, such as arm manipulation or conveyor belt loops. Modern applications, on the other hand, are much simpler, involving tasks like camera rotation or precise mechanical beam redirection for laser radar sensors. You might be surprised to find that the most basic applications of motors are in devices like fans and pumps, which play a crucial role in cooling and hydraulic systems.

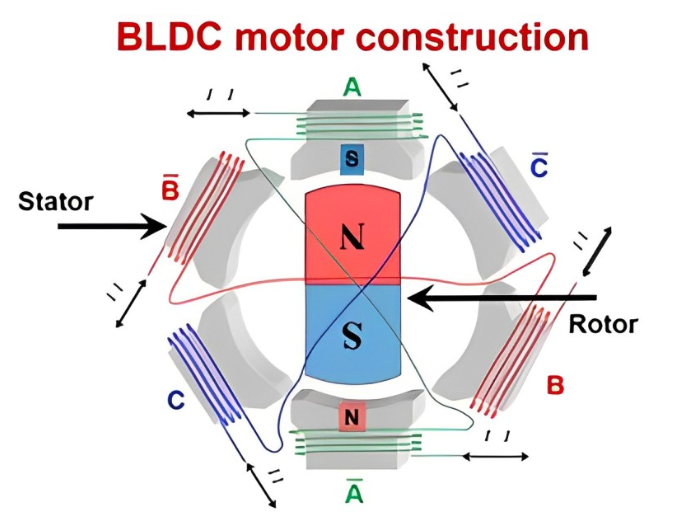

For example, brushless DC (BLDC) motors in robotic arm joints typically consist of a rotating rotor and a stationary stator. Applying an electrical signal to the coils on the stator can generate a magnetic field, creating a force that moves the rotor and, in turn, rotates the joint within the robotic arm. Through judicious use of electronic signals, the robotic arm can not only move but also achieve specific speeds, positional accuracy, and torque control.

Apart from tasks involving precise and powerful movements, advancements in motor control semiconductors, such as microcontrollers (MCUs) and integrated motor drivers, are optimizing the way robots move. However, achieving this goal presents four major challenges.

In the past, for safety reasons, humans and robots needed to be strictly separated, often by placing robots inside cages. The increasing level of automation calls for closer human-robot collaboration, which can enhance work efficiency. However, it necessitates motors capable of ensuring safe stops, safe speeds, torque control, and motion control. Devices like the C2000™ 32-bit TMS320F28P650DK MCU play a crucial role in meeting these safety requirements. These devices have safety certifications and can integrate safety peripherals for diagnostics, simplifying compliance with the International Organization for Standardization (ISO) 10218 standard. On the analog side, smart gate drivers like DRV8353F, with TÜV SÜD certified technical reports, can help engineers achieve their safety objectives as per the IEC 61800-5-2 standard. Whether it's an MCU or gate driver, certain components can streamline the design process for achieving a functionally safe motor system.

Send TMS320F28P650DK MCU RFQ

Motor electronics are transitioning from control cabinets to direct integration within robot joints, reducing weight, simplifying wiring, and cutting system costs. This trend has led component manufacturers to develop solutions that integrate more functions into smaller integrated circuit packages. Space constraints also demand higher power density and power efficiency. Gallium nitride field-effect transistors, like the LMG3422R050, integrate gate drivers, raising power stage efficiency to over 99%, reducing or eliminating the need for heat sinks in integrated motors.

Using MCUs like the TMS320F28065, with real-time communication peripherals and absolute encoder interfaces, systems can generate picosecond-resolution pulse-width modulation signals. These features reduce the wiring from over 10 cables per motor to just two shared bus lines for the entire robotic arm. With MCUs and GaN field-effect transistors in this configuration, designers can optimize wired connectivity by adding single-pair Ethernet functionality through devices like the DP83TG721.

Product miniaturization affects the choice of motors (servo, stepper, or brushless DC motors) for many applications, and the complexity of motor control and position feedback increases to enable precise interaction with these smaller products. Semiconductor innovations make it possible to achieve the higher precision required for product miniaturization. For instance, current sensors like the AMC3306 have a ±50µV offset voltage and integrated power supplies. Integrating these features in a single package can enhance control loop precision and reduce the overall size of printed circuit boards.

Robots are no longer confined to fixed locations; their applications are moving towards mobility, aiding in tasks such as automated parcel delivery and terrain exploration. Semiconductors for sensing, processing, and real-time control applications must balance high performance and power efficiency to ensure reasonable battery life and potential travel range.

Achieving high power efficiency is not necessarily complex and does not require a complicated design with multiple discrete components. For example, a single motor controller like the MCT8316A can effectively operate small pump and fan motors in robots by reducing the number of power-consuming components. This highly integrated device includes six metal-oxide-semiconductor field-effect transistors that form a half-bridge power stage for motor current delivery, along with a digital core for simple trapezoidal motor control without the need for code writing.

The robots of the future will undoubtedly perform tasks beyond our imagination, such as frequent operations in the deepest ocean trenches or venturing into uncharted space. New designs may incorporate increasingly advanced sensors, much like the laser radar and ultrasonic technologies we see today. From wired robots of the past to more software-oriented solutions today, the way we interact with robots may even change. Enhanced accessibility may allow us to control robots more reliably through voice, visual expression, or even mere thought. In this evolutionary process, as robot technology and applications continue to evolve, the motors required to drive their movements are also likely to advance continually.