April 16, 2021

2795

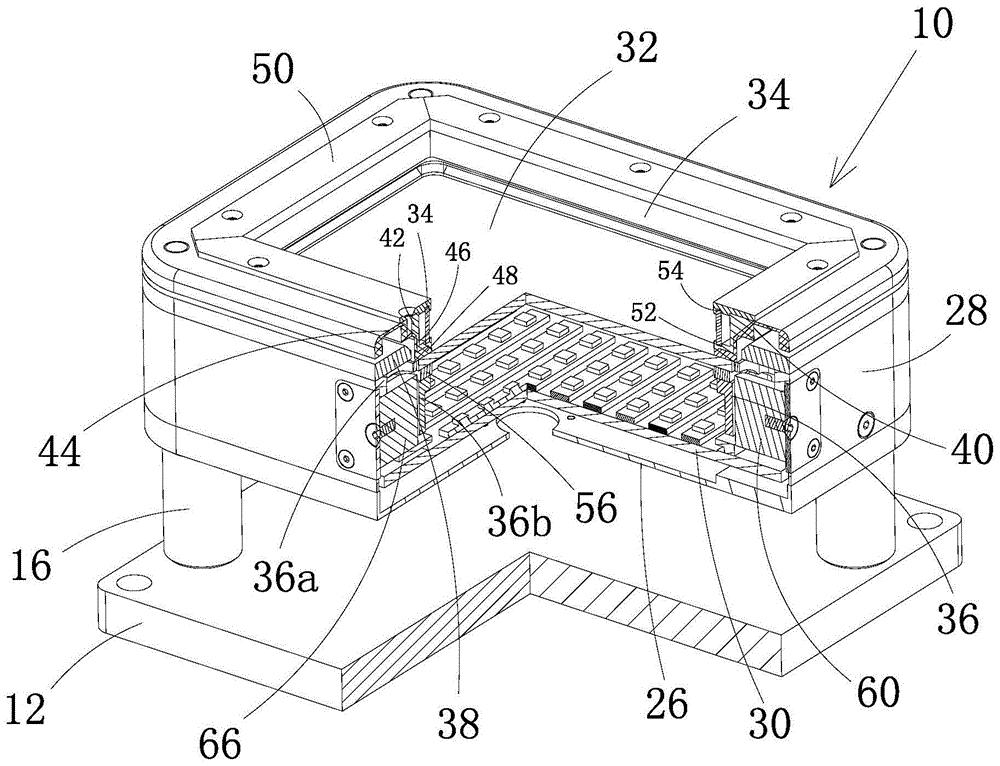

The flexible vibrating plate is suitable for the arrangement and feeding of 99% of the small parts and bulk materials in the industrial automation production. It is also called the flexible feeding plate, the flexible vibrating plate, and the flexible feeder. Flex flexible vibrating plate has five specifications, namely FF100-FF500, which can solve the problem of feeding parts of different sizes, materials, and special-shaped products. In the current rapid development stage, some will require frequent switching of material production, but Flex's flexible vibrating plate is shared, its feeding system does not need to change the hardware structure, and the program switches production varieties with one key, which caters to the current intelligent manufacturing small batches , Flexible production needs of multiple varieties. No jams, no loss of products, good quality flexible feeders are what everyone wants. As the saying goes: shop around, you might as well take a look at Flex's flexible vibrating plate, what are its advantages and how does it work?

The working principle of the flexible vibrating plate:

1. First, manually feed the material to the storage bin, and then vibrate the storage bin to the flexible feeder tray;

2. Then the flexible feeder can move the parts in any direction on the surface of the tray, quickly oscillate and arrange the parts;

3. Secondly, the FF SIGHT vision system CCD photographs the appropriate part shape and position information in the picking window of the material tray, and sends the coordinate data to the robot;

4. Finally, the robot sends the coordinate data based on the vision system, and grabs the parts from the surface of the feeder tray for array panning or assembly

The advantages of Flex flexible vibrating plate:

1. It is suitable for the arrangement and feeding of 99% of small parts and bulk materials in automated production, such as thin slices that cannot be separated by traditional vibrating disks, and special-shaped workpieces.

2. It can be compatible with many types of materials, and the program can switch production varieties with one key.

3. Vibration response is a few ms, as short as 100-1000ms to complete vibration dispersion

4. The material of the tray can be selected from black, FDA food-grade materials, ESD anti-static materials, etc., and can also be structured. According to the special-shaped state of the material, it can be digging holes, grooves, wire drawing, etc. for fast and accurate positioning, identification and grabbing

5. There are 11 movement modes, which can make the material move in any direction of the tray