April 09, 2021

1887

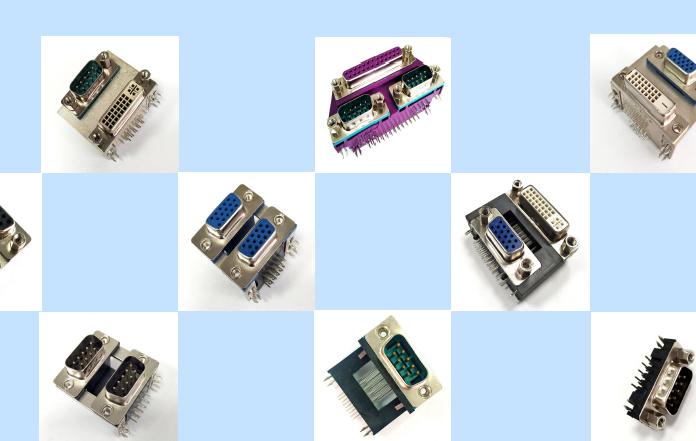

Connectors are electromechanical components that connect conductors (wires) with appropriate counterpart components to realize circuit connection and disconnection. Also known as connectors, plugs and sockets in the country. With different application objects, frequency, power, application environment, etc., there are various types of connectors. For example, there are aviation plugs, aviation sockets, etc. in aviation, while waterproof connectors, cable connectors, etc. can be used in life. In today's society, connectors are widely used in military systems such as aviation, aerospace, and national defense.

1. The selection of the connector series is based on the application environment of the required product:

1. Wireless base station

2. Transmission equipment, switching equipment

3. Backplane, set-top box, network card

The selection of connector series is based on product performance and mechanical requirements, such as impedance matching, VSWR, highest frequency, transmission power matching, etc. A typical application environment can lead you to link up the various parts of this product catalog.

1. Wireless base station

Wireless base stations need to transmit high-power radio frequency signals, high-speed digital signals, and similar signals.

The input/output ports of the equipment casing generally use N-type and 7/16-type connectors. Embedded RF modules require blind matching series such as BMA series, DIN series embedded modules (MARCONI) and panel connectors. Input/output modules use MCX , Surface Mount Series, Panel and Cable Connector. Finally, semi-rigid cable assemblies and flexible cable assemblies are used to complete the signal connection of each part of the entire device.

2. Transmission equipment, switching equipment

In today's large-capacity transmission equipment market, such as voice transmission, data transmission, and image transmission, Jipin provides a large number of high-performance radio frequency connection products. Including connectors, cable components, various consumables, from the central office to the user, from the basic equipment to the set-top box, from 50Ω to 75Ω, all use small RF coaxial connectors; such as BNC series, TNC series, and ultra-small Such as MCX, SMA, SMB, SMC and their miniaturized versions SSMA, SSMB, SSMC. Miniature such as MMCX, it provides extremely high mounting density. In the DIN and IEC standard interface, high-speed signal transmission requires high-performance BNC connectors in the GHz band.

Between transmission equipment and switching equipment, wiring equipment is used. This requires the DDF series connector.

Digital Distribution Frame DDF (Digital DistribuTIon Frames): With the development of communication technology, high-capacity SDH, ATM and other equipment are widely used, which requires the corresponding development of the RF coaxial connector of its basic components, and it has to be more bulky. Smaller, wider frequency band, better performance, more reliable connection. Jipin relies on its independently developed RF/microwave connector transition compensation CAD system to re-optimize the L9 (Siemens) series and C3 (AT & T) series commonly used in China , C5 (NEC) series, C6 (Fujitsu) series, ERI (Ericsson) series and other series of connectors. Make it more reliable and better adapt to future high-speed communication requirements.

The three series of wiring systems C4, SMZ and CC4 developed by Jipin in accordance with international standards use connectors, innovative modular design, smaller size, high applicable frequency and excellent electrical performance.

3. Backplane, network card and set-top box.

In recent years, the coaxial connector market has developed rapidly, and BNC type connectors account for a large number of applications in coaxial export Ethernet applications that provide high-speed channels.

In the lower layer of the communication link, BNC series connectors are widely used. The BNC series has the characteristics of convenient insertion and removal because of its unique bayonet locking method, which makes it widely used.

Recently, because the SMB series connector can improve the density of connector installation, and because of its excellent performance, it can be used for both general commercial applications and military use, so some users gradually choose to apply the SMB series.

In fact, there are multiple solutions for the same application, and users can choose their own suitable connectors according to their needs.

Choice of connecting mechanism:

The connection mechanism makes it possible for the two connectors to be connected to each other, which depends on the required quality and impedance characteristics of the mating connection of the two interfaces, as well as the frequency of operation. The connection mechanism has a great influence on the performance of the connector. The following are five common connection mechanisms.

Screwed Coupling Mechanism (Screwed Coupling Mechanism) uses a connecting nut to connect. Pay attention to limit the maximum torque to prevent the nut from slipping. Connectors with threaded connection mechanism have the following series, SMC, SMA, TNC, N, 7/16, SSMA, CC4, L9, because the threaded connection is relatively firm and reliable; it is mainly used for testing equipment, military and telecommunications equipment.

Push-on coupling mechanism: (Snap-on Coupling Mechanism) Push-on coupling mechanism is mainly used for small interface connectors, and its installation density is relatively high, because this coupling mechanism is more convenient and easy to use, it is often used for printing The connection on the circuit board (PCB).

The push-in connection has a reed for locking. Its advantage is that it is very quick and convenient to insert and remove. This connection mechanism is mainly used in small connector series such as: MMCX, MCX, SMB, SSMB, SMZ series.

Slide-on Coupling Mechanism (Slide-on Coupling Mechanism) Slide-on coupling mechanism is generally used in high-density installation occasions. It is very easy to plug and pull. This type of connector is mainly used in board-to-board coaxial connection systems. in. This kind of connection mechanism is mainly used in small DIN multi-terminal connectors, such as BMA, C4, C5, C6, ERI. They are usually installed in a modular manner.

Bayonet Coupling Mechanism (Bayonet Coupling Mechanism) Bayonet Coupling Mechanism has a pair of locking slots. This locking mechanism is unique to BNC (Bayonet Navy Connector).

Bayonet connection mechanisms are usually used in applications that require reliable connections and quick insertion and removal, such as test and measurement equipment and military equipment.

Push-Pull Self-Latching This connection mechanism has a unique self-locking method.

It is as fast and convenient as a slide-in connection when plugging and unplugging, but it is very reliable. When it is self-locking, it will not unlock even if the cable is pulled. Push-in self-locking is usually used on small connectors with high-density installations such as: 1.0/2. 3, 1.6/5.6 series. It plugs in and out quickly and locks reliably.