December 18, 2020

2578

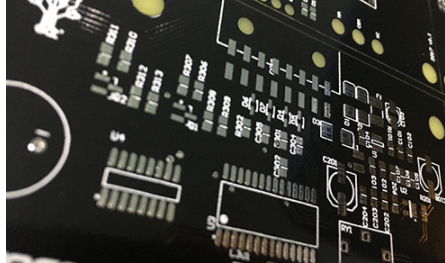

Engineers have done PCB layout for many years and summarized some main areas of concern, among which the Power loop is a place worth considering. So, how to do the Power loop in PCB board design?

1. The more important part of the power board is to bear the power circuit. When laying out, you should first know the circuit characteristics of the power part. The power circuit is mainly divided into DI / DT circuit and DV / DT circuit. The layout of the two lines when walking Different.

The DI / DT circuit is relatively large when the current changes per unit time, so this part of the circuit should be as small as possible for the loop area of the entire circuit. The voltage change of DV / DT circuit in unit time will be relatively large, which is easy to cause external interference. Therefore, the copper skin of this circuit should not be too wide in the loop. It is different when the bearing current is satisfied and the copper skin width is as small as possible. The layer overlap area is as small as possible.

2. The line of the driving part should first consider the area of the entire driving ring, as small as possible to keep away from the interference source and as close to the driving part as possible.

3. The sampled signals must avoid interference with other signals as much as possible. If possible, the sampled signals can be sampled differently, and a complete ground plane is given to them at the corresponding wiring position.