November 17, 2020

2880

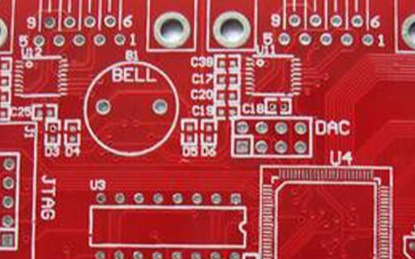

The printed character ink on the PCB circuit board solder mask is not clear. What is the cause? How to solve these problems, we analyze and solve them from four aspects.

1. Preparation and inspection before printing;

For the intermittent and unclear parts of the printed character image, first we observe whether the screen of the screen frame is in good condition, whether the image of the characters is made clear, whether the printing ink scraper is covered and whether the scraping is flat, whether the assembly of the screen frame is flat , And whether the pressure is uniform, the net height balance, and whether the pressure of the screen printing ink scraper is appropriate. If all of these are checked and they are in accordance with the standards, it should be noted that after multiple printings, the screen must be washed with paper to avoid excessive drying of the circuit board solder mask on the screen, which may cause the screen to block.

2. Impressions of fixed screen frames and non-fixed screen frames;

PCB circuit board solder mask printing screen frame is roughly divided into fixed type and non-fixed type. If you are using a non-fixed frame, it is more convenient to fine-tune the screen, but the blurring caused by printing is more likely to occur. The fixed frame is generally calibrated before printing due to the tension. Compared with the non-fixed type, the tension is even and stronger, and the printing problem of uneven tension is not easy to occur.

After the screen is stretched, it must be allowed to stand still to release the stress. The residual stress will cause insufficient printing accuracy and blurred printing. It is recommended to use a fixed frame. If you follow the standard procedures to make screen-printed images, the problem of unclear printing of thermoset text ink is less likely to occur.

3. Whether the ink scraper is suitable;

The sharpness of the squeegee is also one of the factors that cause unclear printing. The ink printing squeegee must be polished regularly to maintain good printing habits, because a dull knife can easily pull the screen to produce printing shadows, which makes the printing of text ink unclear.

4. Whether the solder mask on the PCB circuit board is clean;

After the solder mask is printed on the PCB circuit board, the character ink needs to be printed in the later stage of the circuit board. The surface must be cleaned before printing. If the solder mask on the surface of the circuit board is not cleaned, it is easy to combine when printing text ink. Insufficient force to fall off or non-stick phenomenon, this will also cause the printed text ink to be unclear, so before printing, we must pay attention to the cleanliness of the solder mask surface.

The above are the general reasons why the printed text ink of the PCB circuit board solder mask is not clear. If the improvement cannot be solved, it is recommended to change to a better silk screen text ink. Some low-end circuit board thermosetting text inks are due to Quality problems and poor printing performance can also cause unclear ink printing.